VISIMPEX SOLAR - A naprakész rögzítés

Mit kell tudni a napelem tartószerkezetekről?

A tartószerkezetek a napelemes rendszerek fő összetevői közül a legkisebb költségű tételek, de ugyanúgy nélkülözhetetlen rendszerelemek, mint a napelemek vagy az inverter.

Anyaguk szerint a VISIMPEX SOLAR rendszer - a napelemes energiapiac szakmai szabályainak megfelelően - kizárólag alumínium és rozsdamentes (A2) termékekből épül fel.

Miért ajánljuk Önnek a VISIMPEX SOLAR rendszert?

Mert úgy gondoljuk, hogy jó terméket szeretne vásárolni, hosszútávra. És értékelni fogja a VISIMPEX SOLAR rendszer nyújtotta biztonságot. A kiváló minőség és a folyamatos innováció mellett kiemelt figyelmet fordítunk a műszaki támogatásra is, ami fontos érv a VISIMPEX SOLAR rendszer mellett, akár családi, akár nagyobb méretű projektről legyen szó. Továbbá a kedvező ár-érték aránnyal párosuló minőség mellett kevesebbet kell költenie karbantartási költségekre is, ezzel pedig pénzt, időt és nem kevés kellemetlenséget spórolhat meg. Na, és mert számunkra nincsen lehetetlen: a VISIMPEX SOLAR rendszer megoldást nyújt a sík - vagy a ferde tetőre elhelyezett, valamint a szabadonállóan szerelt napelemes erőművek professzionális rögzítéstechnikai igényeire éppúgy, mint az egyedi megoldásokra. Igény esetén akár a helyszínen felmérünk, tervezünk, ajánlatot készítünk, gyártunk és gyorsan, pontosan, határidőre szállítunk!

Tekintse meg termékkínálatunkat az alábbiakban, további felmerülő kérdéseivel pedig forduljon bizalommal VISIMPEX SOLAR szakértő értékesítőinkhez, akik készséggel állnak rendelkezésére!

Referenciáink

Tetőválasztó

1. Ferdetetős rögzítések

1.1 Beton és cserépfedések

Hullámos és egyenes fedésvonal

Ezek talán a leggyakrabban használt tetőfedő anyagok, amelyek változatos és tetszetős tetőburkolatok kialakítását teszik lehetővé.

Alkalmazhatók közepes és meredek hajlásszögű tetőhöz is.

Kiselemes mivoltából adódóan a tetőkampók, elhelyezése pontszerűen fedés elmozdítással, bontás nélkül megoldható.

Egyenes és hullámos fedésvonakú kialakítások mellett méretnövelt termékek (XXL) is helyet kaptak a hazai piacon melyek ismeretében lehet a megfelelő tetőkampót kiválasztani.

Hullámos fedésvonal |

Egyenes fedésvonal |

1.2 Bitumenes zsindelyfedések

Különféle típusai igen változatos fedésképet adnak. A különféle méretű és alakú, adalékanyagokkal kevert hálós hordozó alapra készített bitumenes fedőelemeknek könnyű a felerősítése, azonban nehezen mérhető a fő tartószerkezet pozíciója.

A rögzítő elemeket tetőkampókat ászokcsavarokat a fő tartószerkezethez kellé rögzíteni!

Bitumenes zsindely |

1.3 Fémlemezes tetőfedő anyagok

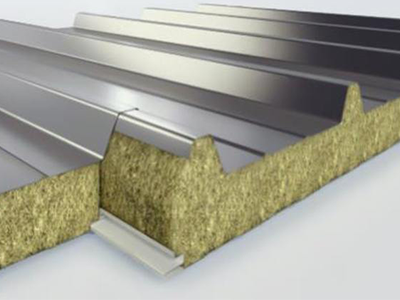

Trapézlemez, szendvicspanel és cserepes lemez

Ide sorolhatók a különféle fazonú trapézlemezek, cserepeslemezek és szendvicspanelek. Anyaguk lehet horganyzott acéllemez vagy alumínium is.

A kínálatuk meglehetősen bőséges, emellett könnyűek, a hagyományos cserepek súlyának csupán 1/10-e, ami könnyebb fedélszék kialakítását teszi lehetővé.

Figyelem! A lemezfedéseket is rendszeresen helyezik el meglévő rosszállapotú fedések fölé, így a standard megoldások nem megfelelőek a telepítéshez !!!

Alépítmény függvényében a megoldása: TR43, Tr310 profilrendszer, ászokcsavaros megoldás, egyedileg tervezett elemek

Trapézlemezes |

Szendvicspanel |

Préselt lemezfedés

Napelem telepítés szempontjából bontás nélkül nem kivitelezhető fedés. Felméréskor különös figyelemmel kell lenni, mert a profilozása és felületképzése miatt sok esetben nehezen megkülönböztethető a cserépfedésektől.

Létezik a rendszerhez tartozó gyártói tetőkampó amit Csak a fedés telepítésekor lehet elhelyezni.

Amennyiben a fedés megfúrásra, bontásra kerül megszűnik a gyári garancia a fedésre!

Vizsgával rendelkező tetőfedő bevonása mellett a fedés garanciája megmarad a speciális tetőkampó beépítése után is!

Cserepes lemez |

Préselt lemez |

Korcolt lemez

Jellemzően réz-cink lemefedések változatos színekben általában 55-60 cm korctávolságokkal. Korcolt és előkorcolt kivitelekben telepítik.

A tetőtartókat a fedés bontása nélkül, szorító kötési módon rögzítik a lemezfedéshez, majd ehhez kapcsolják az alumínium profilokat.

A tartók kivitelére, sűrítésére a tartószerkezet forgalmazója tesz javaslatot.

Korcolt lemez |

1.4 Pala fedések

Síkpala, és hullámpala

A természetes réteges kőzetanyagból hasítással előállított pala – kellő alakra formálás után – esztétikai hatású, nagyon tartós tetőfedő anyag. Az ilyen tetőfedések kialakítását csak e téren kellő gyakorlatot szerzett szakember képes tartószerkezettel ellátni.

A műpala elemek viszonylag hasonló hatásúak a természetes palalemezekhez, ám ezek rostcement műszálak és cementes keverékből sajtolt, vagy hengerelt környezetbarát tetőfedő anyagok. A régebben használt azbesztcement helyett ma már korszerű, környezetbarát szálerősítőket használnak a gyártásukhoz.

Telepítéskor törik, nagyon nehéz szakszerűen javítani!!!

Amennyiben szükséges Megoldása: ászokcsavaros rendszer

Síkpala |

Hullámpala |

Lapos tetőre csak alapos előkészítéssel szabad napelemes rendszert telepíteni.

Megkülönböztetünk tető-áttöréses és ellensúlyos kivitelezési megoldásokat. A tetőáttöréses megoldások fő elemei az épület tartószerkezetéhez kerülnek rögzítésre a vízszigetelés szakszerű helyreállítása mellett. Ez kisebb önsúlyából adódóan kevésbé terheli az épületet azonban magasabb beázási kockázatot jelent.

Az ellensúlyos megoldásoknál figyelembe kell venni az alépítmény terhelhetőségét szakértő vagy statikus bevonásával. Az ellensúlyok mértékére a tartószerkezet forgalmazója tesz javaslatot figyelembe véve a napelemek pozícióját, dőlésszögét.

A helytelen kivitelezések károkat okozhatnak az épület szerkezetében, és akár személyi biztonságot is veszélyeztethetnek.

Lapostetős rögzítés |

A szabadon álló konstrukciók legfontosabb jellemzője, hogy azok a művelési ágon kívül eső szabad területen kerülnek telepítésre.

Ezzel a módszerrel jellemzően nagy, több MW teljesítményű napelemes villamos energiát termelő parkok kerülnek kialakításra. Figyelembe véve a terület környezeti és időjárási adottságait.

Kialakíthatóak talajhoz rögzített (talajcsavaros) és ellensúlyos megoldásai is.

Jellemzően a szerelésük magas logisztikai, erőforrásbeli ismereteket és lehetőségeket igényelnek.

Szabadon álló konstrukció |